The Challenge

Our client required a comprehensive automated solution to handle the packaging of various sausage products into cardboard boxes with integrated palletization. The system needed to accommodate a wide range of product sizes—from smaller sausages (36mm diameter, 100g) to larger products (90mm diameter, up to 2,700g)—while maintaining high throughput and quality control standards.

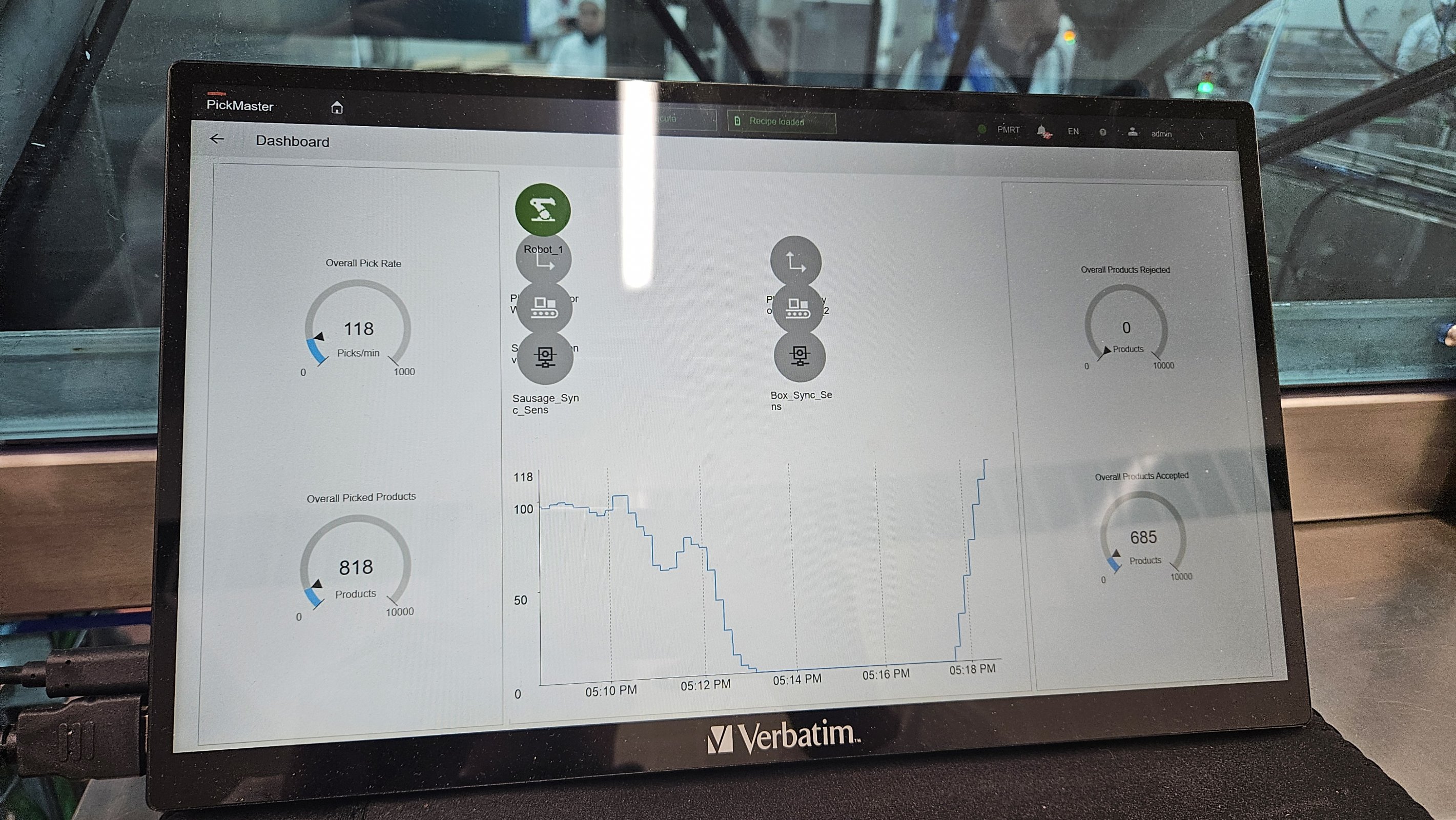

SINEL designed and delivered a fully integrated automatic packaging line capable of processing up to 120 sausages per minute. The complete system seamlessly handles the entire process from string cutting through final palletization, incorporating robotic technology with precision transport systems and advanced control algorithms.

System Components

Primary Processing Modules - String Cutting Machine - Automated removal of hanging strings from sausage sticks

- Sausage Cutting Machine - High-speed separation of individual sausages (180 cuts/min)

- Rotary Accumulation Table - Buffer system ensuring continuous product flow (Ø1500mm)

- Dynamic Checkweigher for Sausages - Individual product weighing with automatic rejection (Bizerba)

- Ink-jet Printer - Direct date coding on sausage casings

- Dynamic Checkweigher for Boxes - Final package verification with labeling option (Bizerba)

- ABB 4-axis Delta Robot - High-speed product handling with 8kg payload capacity

- Automated Box Former - Processes FEFCO 0711 ready-glued cases (15 boxes/min)

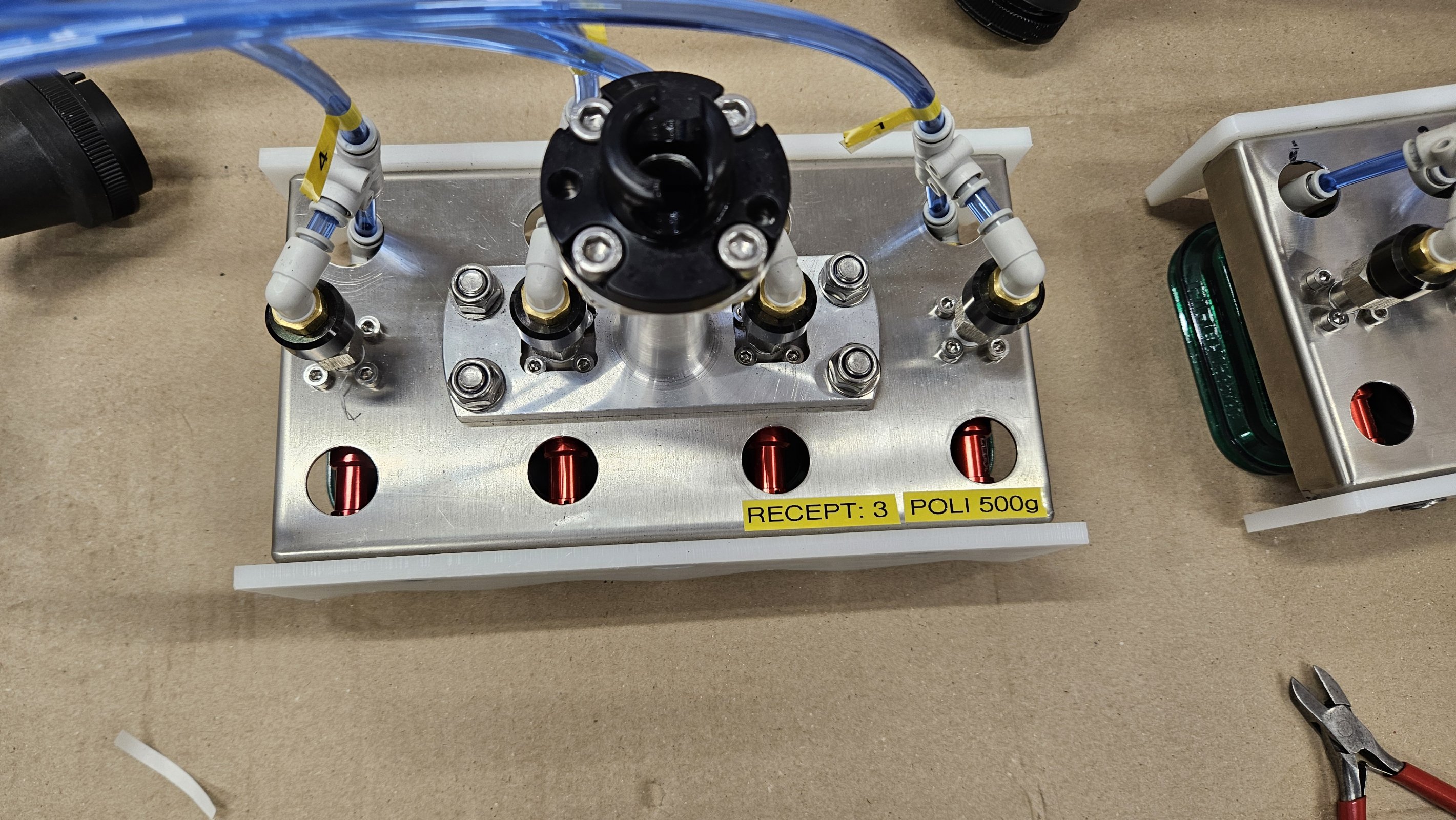

- Vacuum Gripper System - Quick-change capability for different product formats

- Laser Sensors - Precise position detection (±0.5mm accuracy)

- Box Sealing Machine - Automatic tape application to filled cartons

Palletization System

- ABB 4-axis Palletizing Robot - Dual pallet terminal configuration

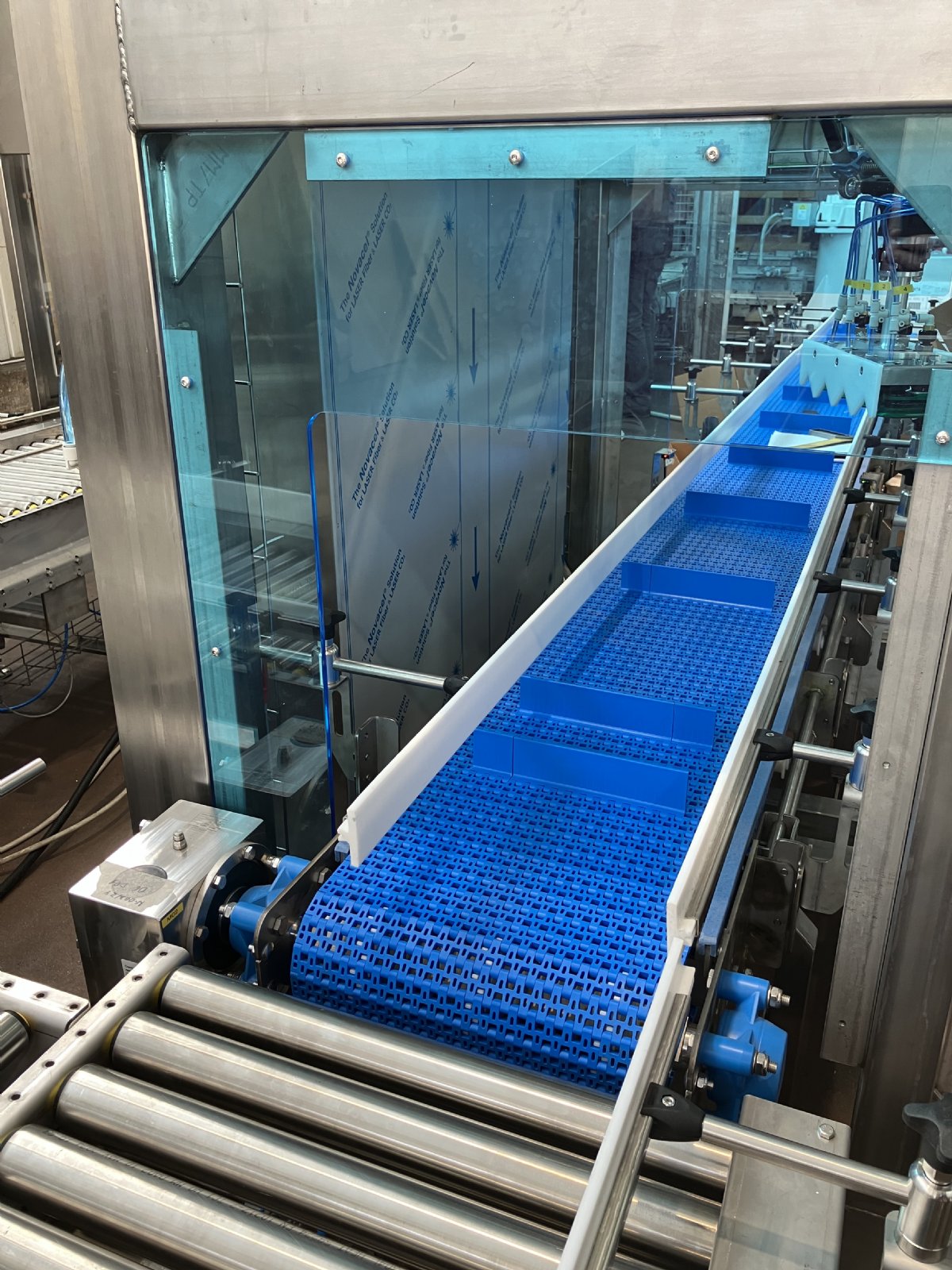

- Accumulation Conveyors - Smooth product flow management

- Configurable Stacking Patterns - Flexible layout programming via operator panel

- Capacity - Up to 10 cartons/minute

Technical Specifications

Product Range Handled: - Diameter: 30-90mm

- Weight: 100-2,700g

- Length: 120-350mm

- Minimum: 190 x 190 x 120mm

- Maximum: 400 x 400 x 180mm

Key Features

Complete Automation - Minimal human intervention required throughout the entire process Dual-Stage Quality Control - Automated weighing at both individual product and finished box levels

Flexible Format Handling - Accommodates 11 different product types with minimal changeover time

Hygienic Design - Stainless steel (AISI 304) construction meeting food industry standards

Centralized Control - Integrated PLC system with real-time performance monitoring and statistical analysis

Safety Compliance - Full safety enclosures and industrial standard protective measures

Results & Benefits

✓ Significant Labor Cost Reduction through process automation ✓ Increased Production Capacity and operational efficiency

✓ Enhanced Quality Control with automatic weighing and defect rejection

✓ Complete Traceability through integrated data collection and reporting

✓ Reduced Human Error in packaging and palletization processes

✓ Improved Consistency in final product presentation

Project Scope

The turnkey solution included complete system design, equipment supply, installation, integration with existing processes, operator training, and comprehensive documentation in the client's language.

Interested in exploring how this project could benefit your company?

Let's discuss your specific needs and explore how our solutions can contribute to your success. Allow us to demonstrate what we believe makes us different, to show you why working with a partner is better than working with a supplier.

Talk to an expert