Challenge

Our client, a supplier for the automotive industry (PSA Group), required a robust and highly efficient solution for the fully automatic assembly of rotating automotive handles. The process involved assembling 9 separate components (including springs, dampers, clips, and pins) into a single unit. The main challenge was achieving an extremely short cycle time (under 7 seconds) while implementing 100% quality control. The system had to automatically test the key functionalities of each assembled handle—specifically, the pin function and the handle return time—and automatically sort correct from incorrect products.

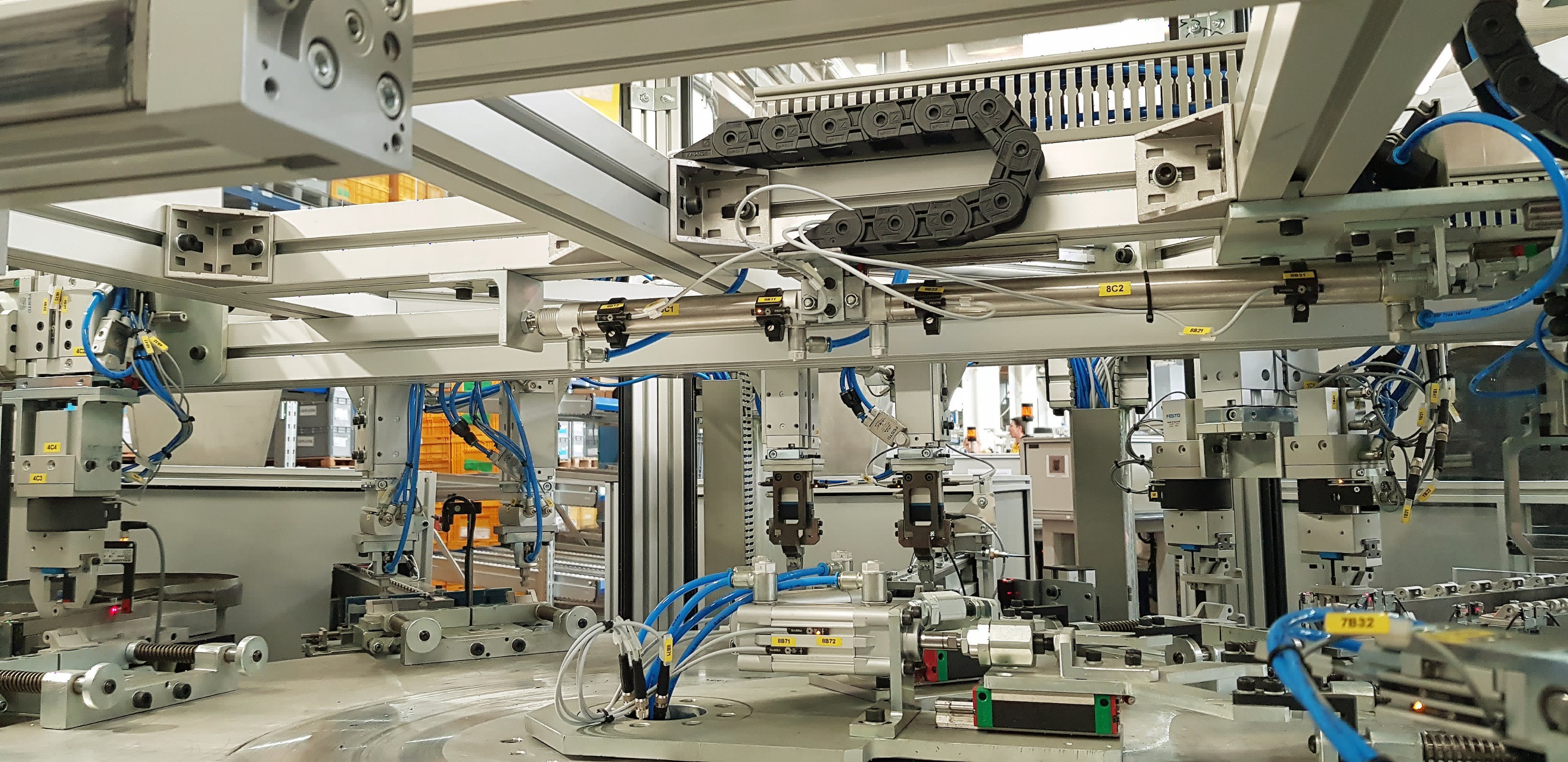

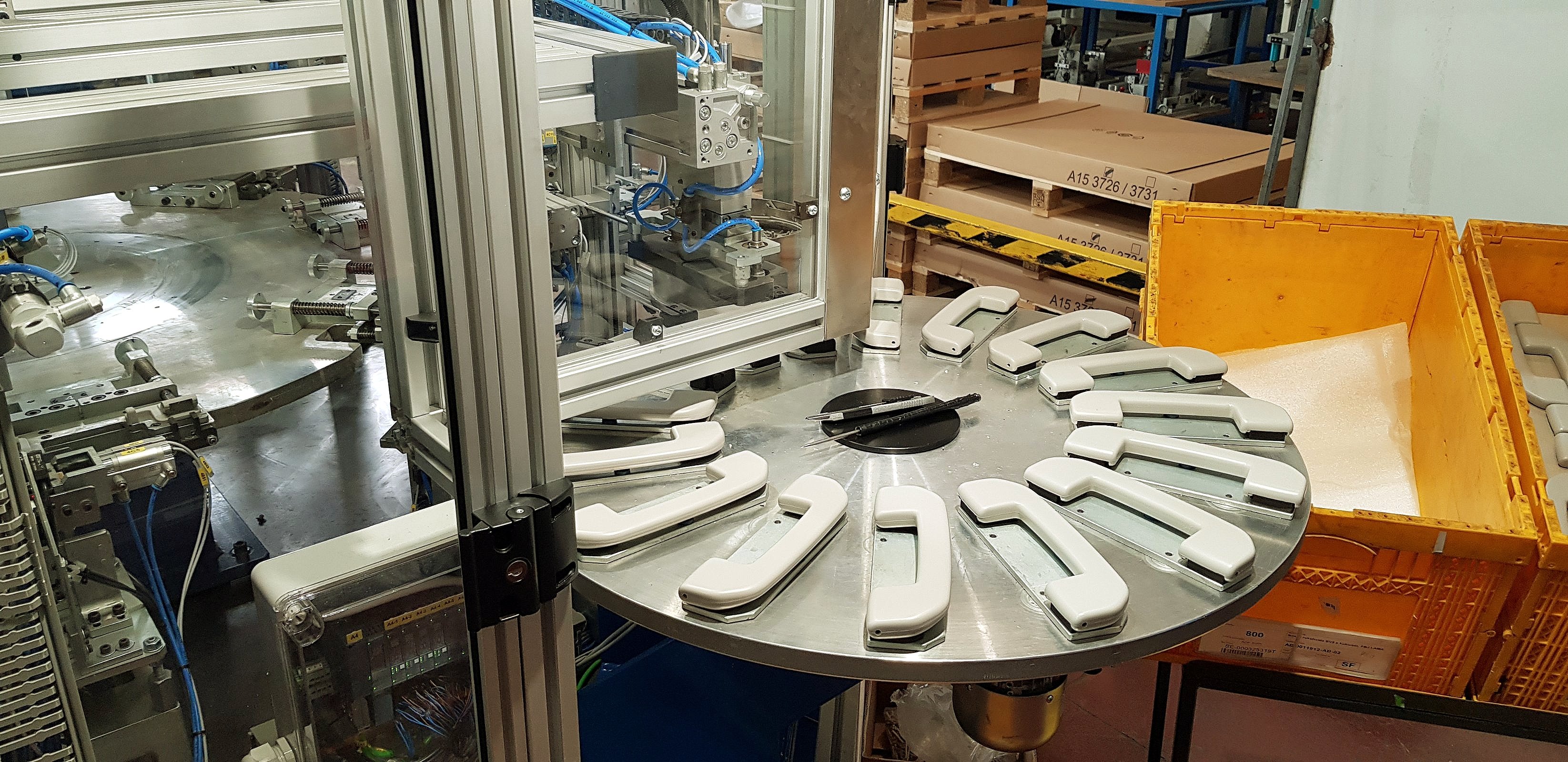

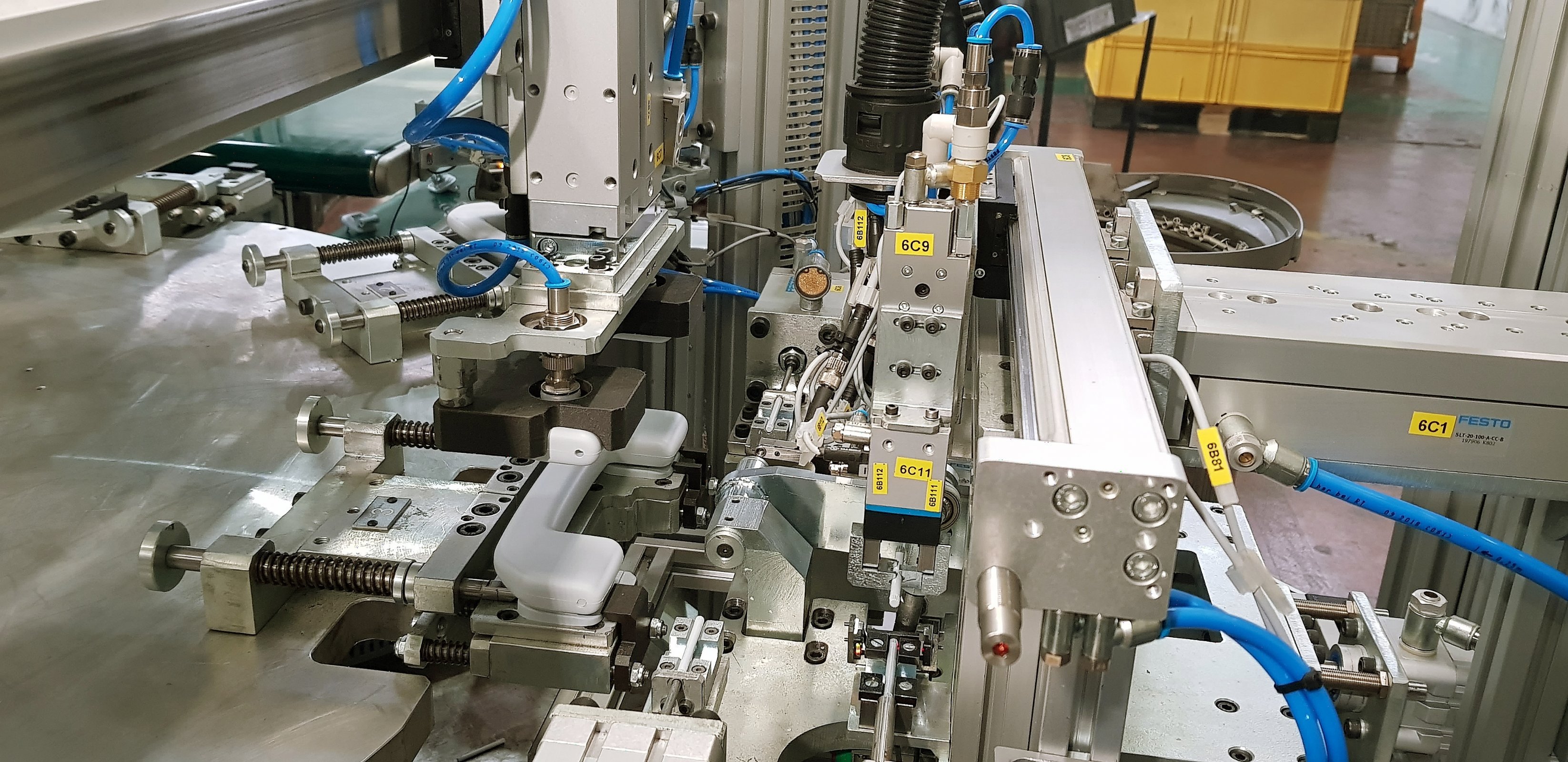

SINEL designed and delivered a "turnkey" solution in the form of an automatic assembly station based on a rotary table. The station uses an eight-position rotary table with eight work nests (pallets), with each position executing a specific step in the assembly process. The entire process, from embase insertion to final control, is fully automated (using 7 vibratory feeders and 2 elevators) with the exception of manually loading the handle body. The solution reliably achieves a cycle time of 7 seconds per piece.

System Components

Primary Assembly Stations - Station 1: Embase Insertion - Automatic recognition and insertion of the handle base (embase) onto the pallet.

- Station 2: Raymond Clip Insertion - Precise insertion of two Raymond clips into the base.

- Station 3: Pin Insertion - Placement of pins (studs) into the Raymond clips using vacuum grippers.

- Station 4: Damper Insertion - Orientation recognition and insertion of the NIFCO damper.

- Station 6: Final Assembly - Automated insertion of the spring and axles, and acceptance of the handle body which the operator places on a separate rotary table.

- Station 5: Pin Function Test - A key check where pneumatic units eject the pins by a defined measure (5 mm) to confirm correct assembly for future body installation.

- Station 7: Handle Return Control - Functionality testing where the system rotates the handle and measures its return time. The assembly is considered correct only if the return time is within the specified range (2.5 - 3 seconds).

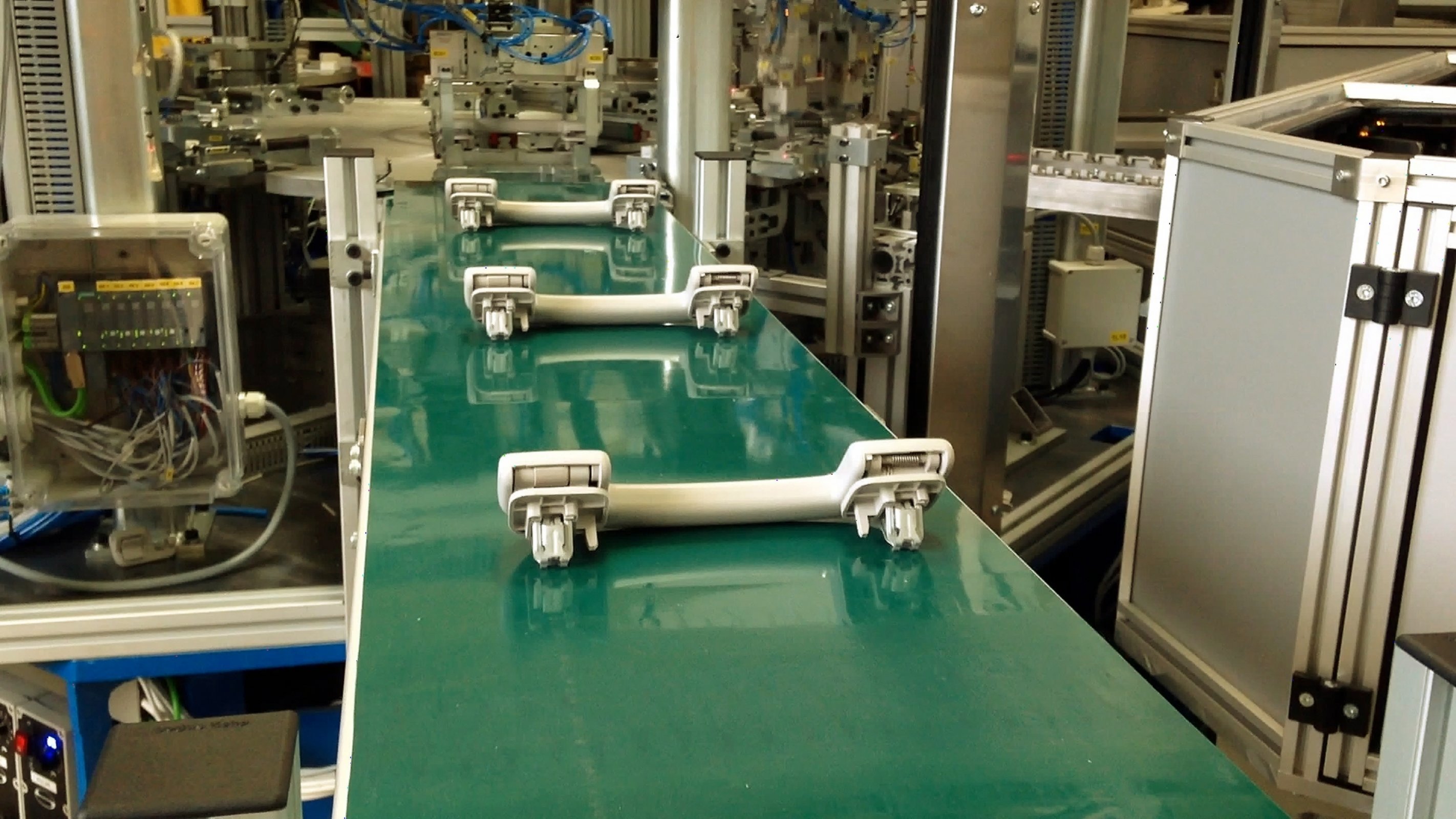

- Station 8: Extraction and Sorting - Automatic separation of finished handles from the pallet. Correct assemblies are deposited onto the upper conveyor belt, while incorrect (reject) ones are automatically routed to the lower belt.

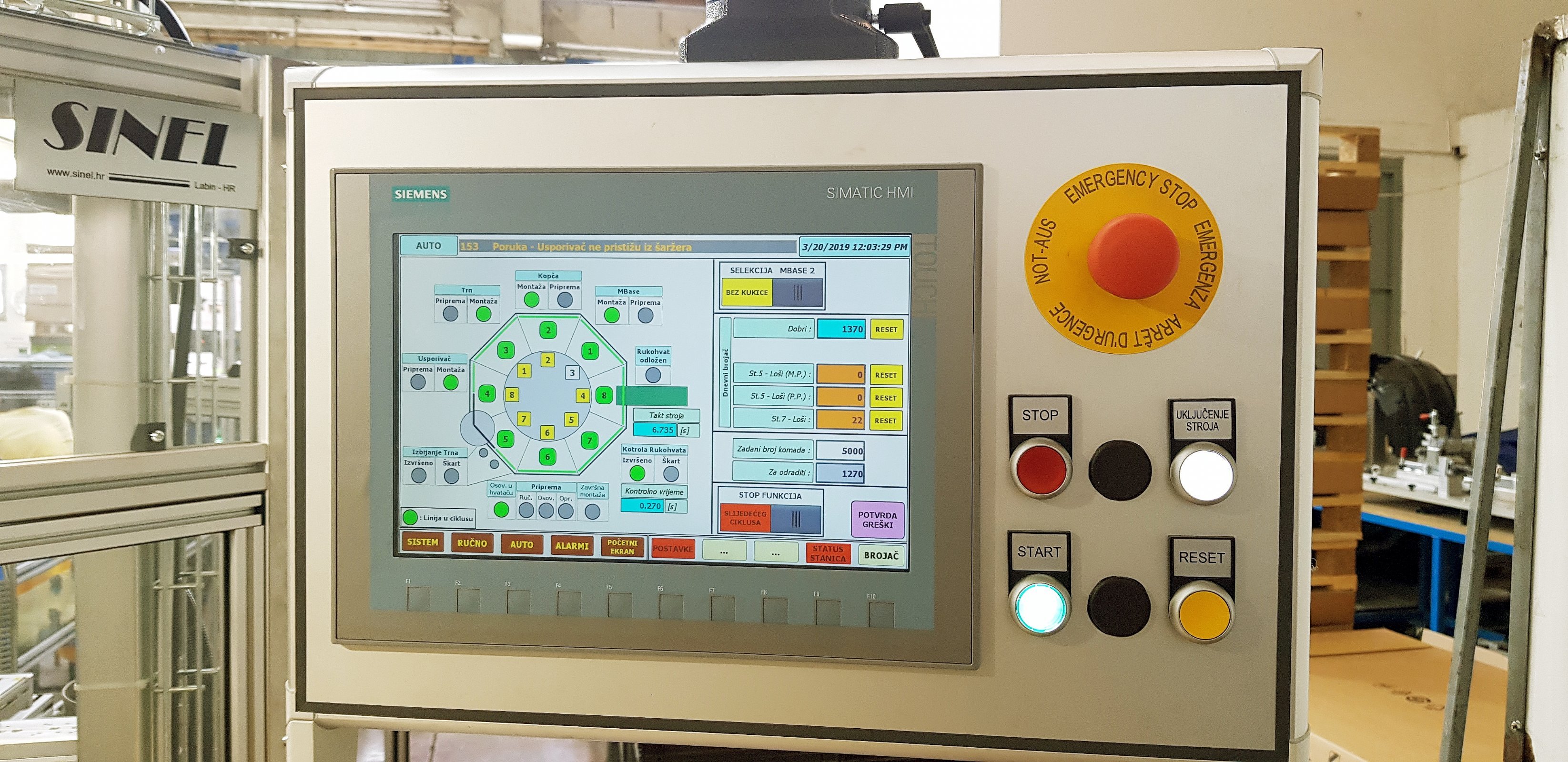

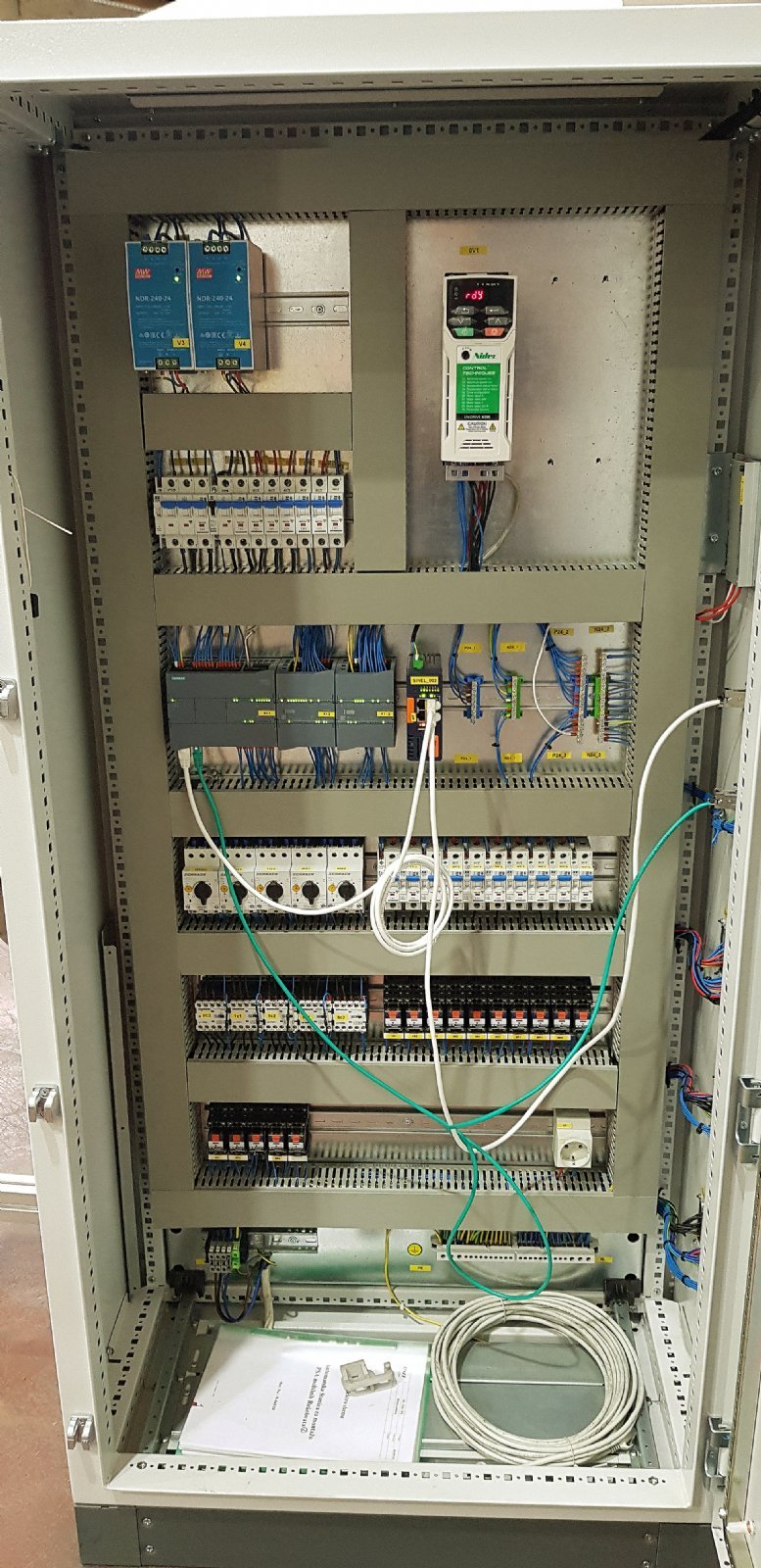

- Central Control - The entire automatic machine is controlled by a Siemens Simatic S7-1500 PLC.

- HMI Interface - The Siemens KTP 1200 Basic TouchPanel allows for easy control, monitoring, and parameter adjustment.

Technical Specifications

Performance: - Cycle time: 7 seconds

- Dimensions (L/W/H): 7500 / 5000 / 2450 mm

- Machine Weight: 3200 kg

- Total Installed Power: 5.0 kW

- Supply Voltage: 3x400V, 50 Hz

- Control Voltage: 24 VDC

- Working Air Pressure: 6 bar

Key Features

High Productivity - A cycle time shorter than 7 seconds enables fast serial production. 100% Automatic Quality Control - Two-stage verification of key functions (pin control and handle return time) ensures a zero error rate.

Automatic Sorting - The system independently separates correct products from incorrect ones onto two different conveyor belts.

Robust Construction - The automatic machine is built on a massive octagonal steel structure, designed for long-term operation in an industrial environment.

Flexibility - The station is capable of completing both front and rear types of handles.

Operator Safety - The entire machine is equipped with a protective casing with sliding and hinged doors secured by sensors, thus protecting the operator during automatic operation.

Results and Benefits

✓ Significantly Reduced Labor Costs due to the automation of the 9-component assembly process. ✓ Improved Consistency and Quality by removing the human factor from repetitive assembly and control processes.

✓ Zero Defect Rate for Shipped Products thanks to 100% integrated control and automatic sorting.

✓ Increased Productivity due to automation and the 7-second cycle time.

✓ Improved Workplace Safety through the implementation of a full protective casing with safety sensors.

Project Scope

SINEL delivered a comprehensive "turnkey" solution which included mechanical and electrical design, PLC and HMI system programming, production, assembly, and commissioning. The project also included the preparation of comprehensive technical documentation and a user manual, as well as the training of operators and maintenance staff.

Interested in exploring how this project could benefit your company?

Let's discuss your specific needs and explore how our solutions can contribute to your success. Allow us to demonstrate what we believe makes us different, to show you why working with a partner is better than working with a supplier.

Talk to an expert