AI-Powered Quality Control for the Food Industry

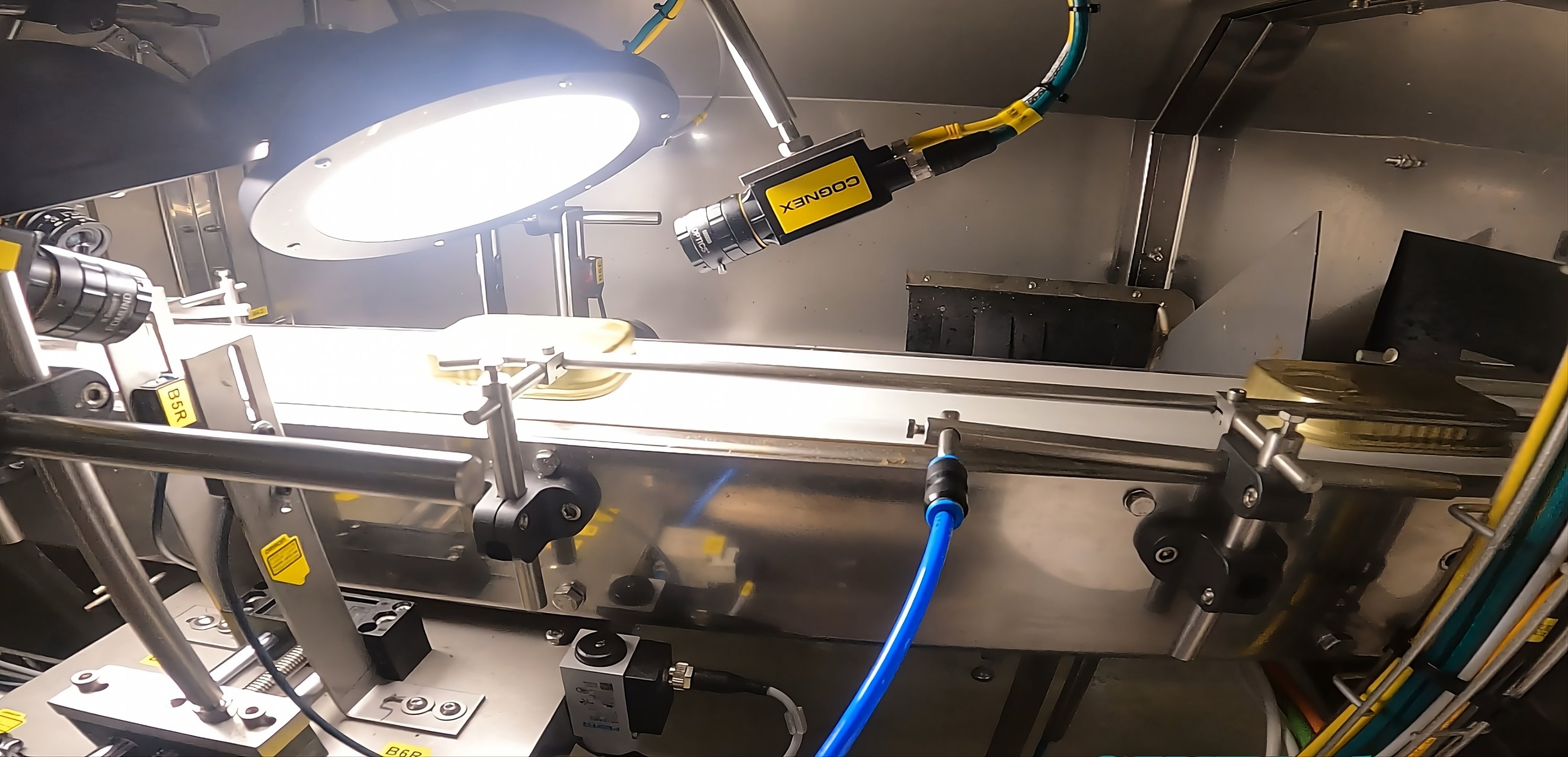

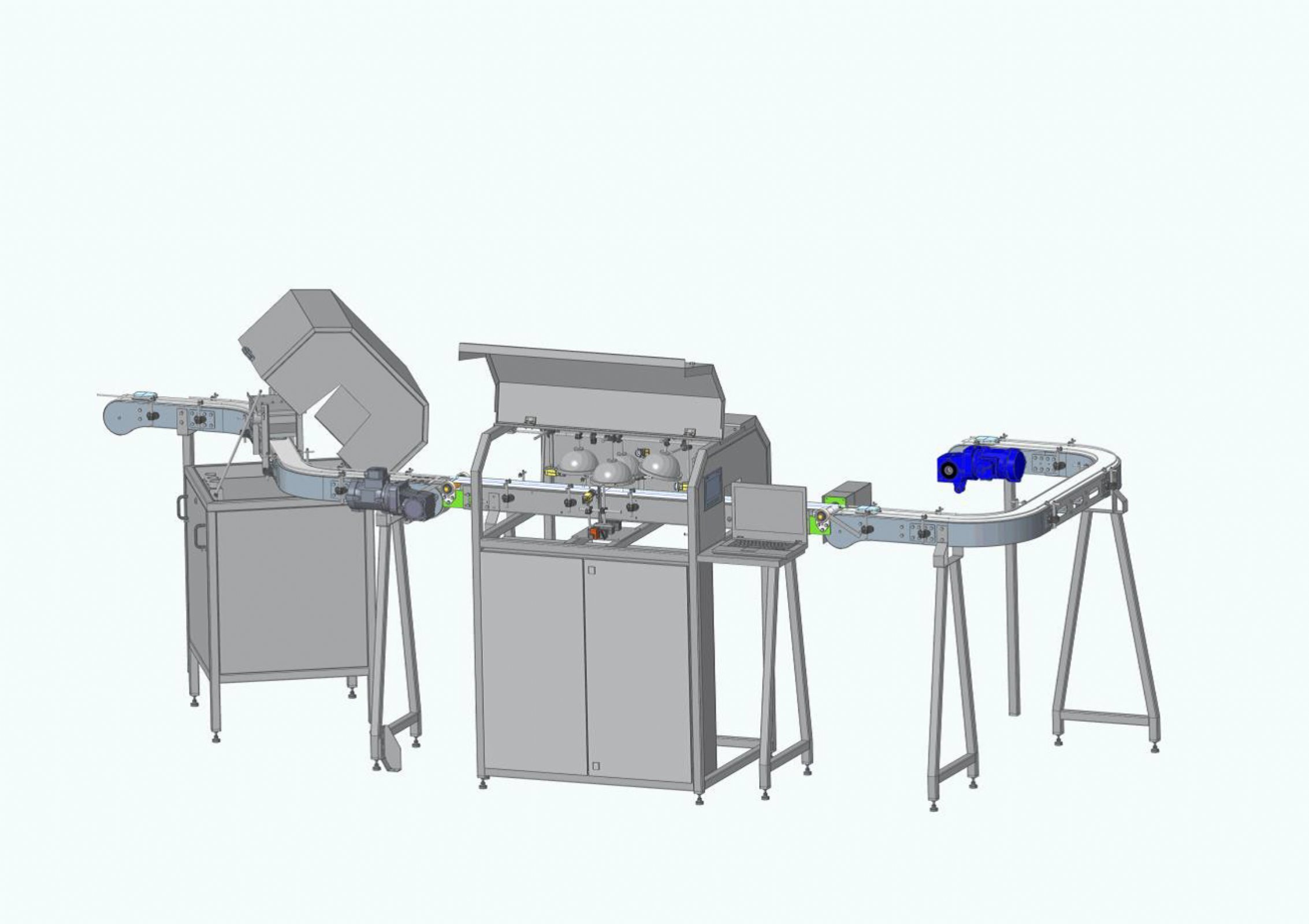

At SINEL, we’re proud to introduce our AI-Powered

Machine Vision system for 100% contactless double seam

inspection of cans — ensuring flawless packaging quality

and zero defects before products leave your line.

Each system is developed and produced in-house at SINEL,

tailor-made for your production needs.

Key Technological Breakthroughs:

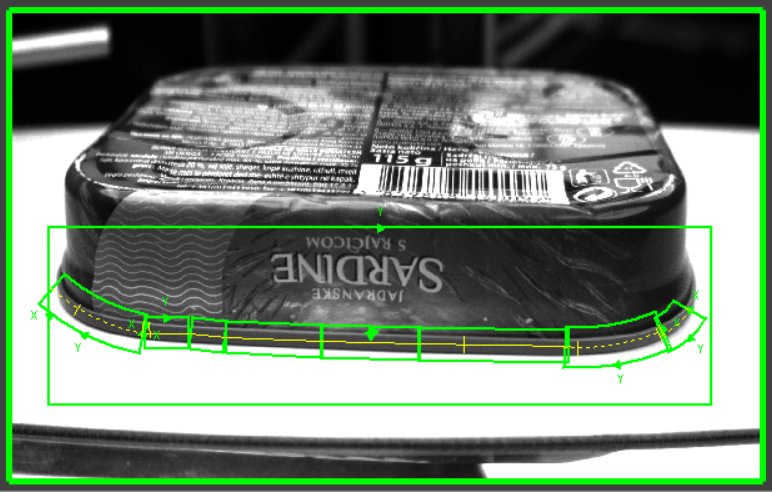

1. Self-Learning

Intelligence: Cameras use self-learning

pattern recognition to learn the "ideal” double seam curve — automatically

detecting and rejecting any deviation in real-time.

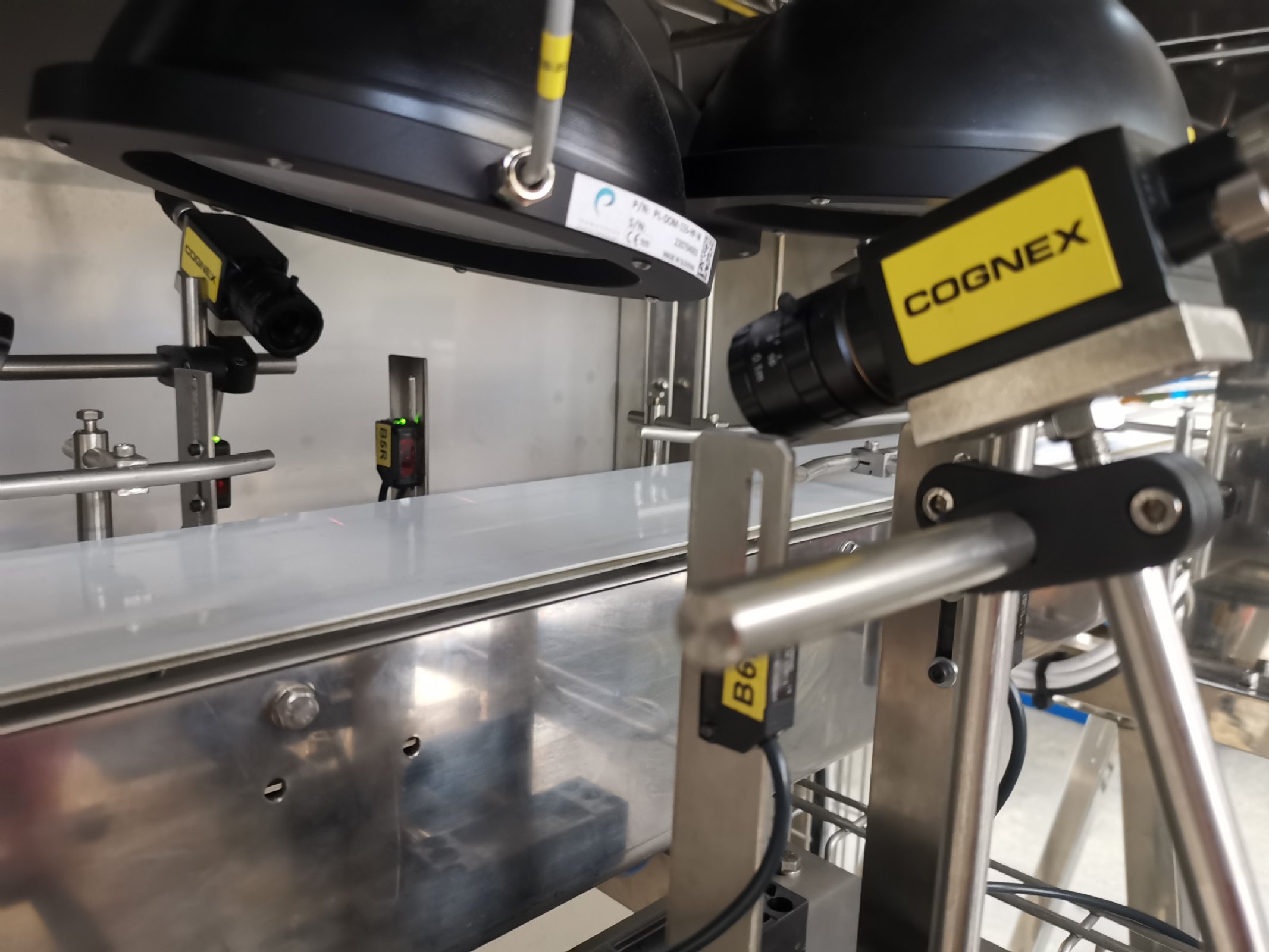

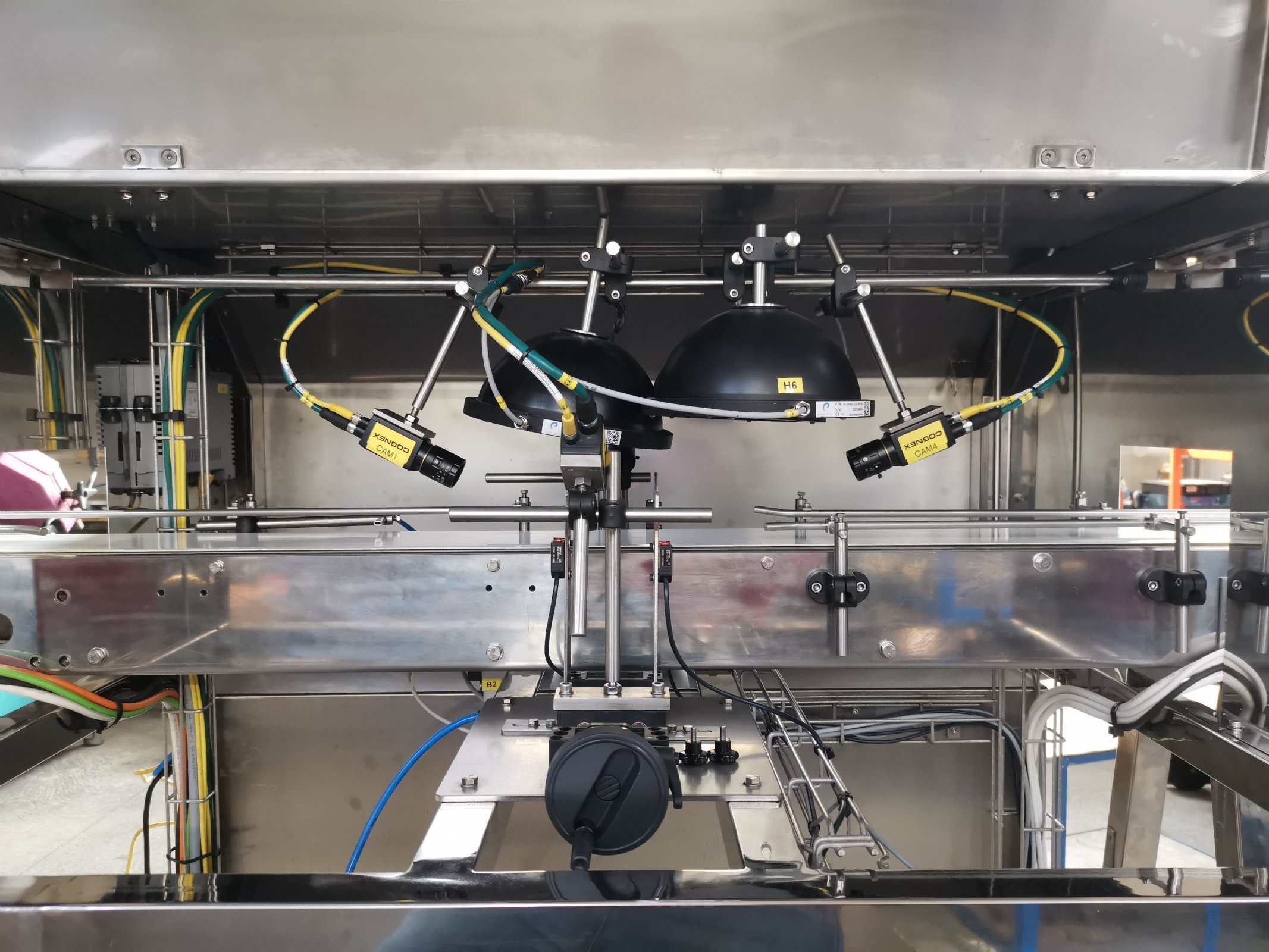

2. System Simplification: Only 4 high-resolution cameras (vs. 6 in competing

systems) — reducing complexity, computing power, and energy consumption.

3. Novel Transport Method: By flipping the can’s orientation, we ensure full visibility of the

lid rim, increasing reliability and eliminating camera height adjustments.

4. Fully Automated

Ejection: Defective cans are instantly removed

using high-pressure air nozzle, captured in slow-motion

precision.

Interested in exploring how this project could benefit your company?

Let's discuss your specific needs and explore how our solutions can contribute to your success. Allow us to demonstrate what we believe makes us different, to show you why working with a partner is better than working with a supplier.

Talk to an expert