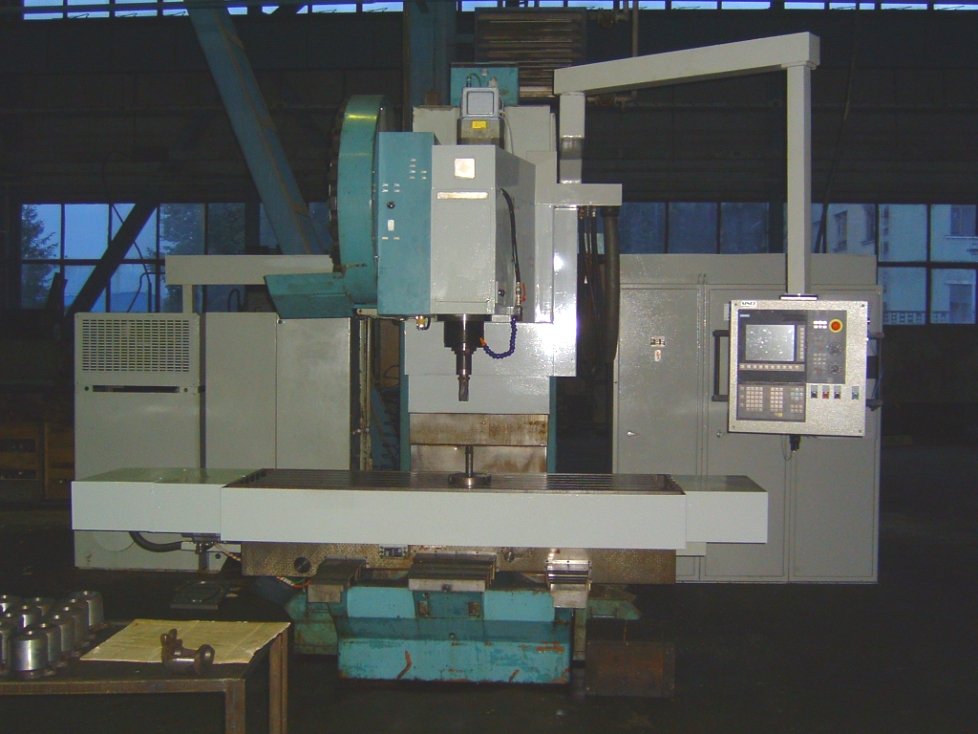

During many years of intensive use of machine tools, machine tool parts are prone to wear. On such machines, in the production process, precision and reliability are lost, product errors often appear, and there are frequent downtimes that make production on such machines more and more expensive. Overhaul and retrofitting of machine tools has many advantages for the owner. The occurrence of scrap is reduced, production cycles are shortened, and the cost incurred due to machine downtime is reduced to a minimum, and in addition, work productivity increases. Overhaul, retrofitting and rebuilding of older machine tools bring them up to the technological level of completely new machines.

- Grinding of the sliding tracks of the machine

- Replacement of bearings, gearbox reducers, pulleys and belts, threaded spindles, nuts and drives

- Detailed laser geometry of the machine is performed

- Replacement of hydraulics

- Replacement of the impulse lubrication system

- Installation or replacement of CNC machine controls together with programming and parameterization (we mainly install numerical controls from Siemens, Heidenhain and Fanuc) Installation of tool changers

- Installation or replacement of measuring systems (digital position readers, rotary encoders and linear measuring systems) manufactured by Heidenhain or Siemens

- Replacement of machine wiring with limit switches and micro switches

- Wiring and installation of electrical cabinets

- PLC programming and parameterization

- Optimizing drives and regulators

- Testing and control of correct operation

- Creation of complete documentation on completed works and installed positions

All jobs are carried out in the shortest possible time according to the actually determined necessary interventions on the machine, and everything according to the previous agreement. Overhaul and retrofitting of machines is carried out in production halls directly next to the company's headquarters or in the client's production premises. We recommend the location where the overhaul and retrofitting of the machine is carried out, where it is possible to reduce labor costs as well as manipulative, transport and customs costs the most.

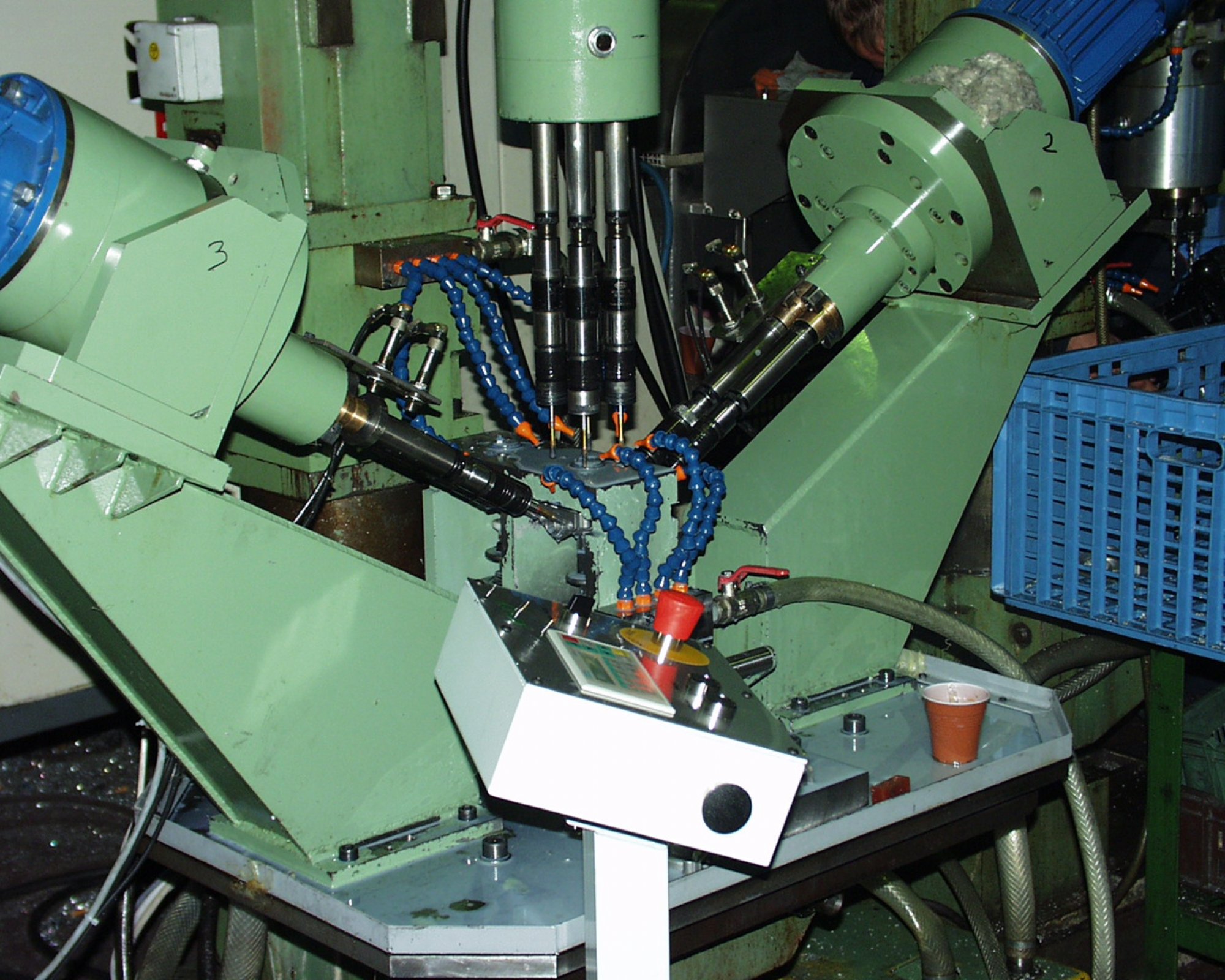

In addition to repair, retrofitting and rebuilding services, we also provide all types of service services and upgrades of electronic and mechanical equipment on machine tools, as well as partial machine overhaul. According to your needs and requirements, we are able to carry out complex modifications of machines so that they fully meet your needs. We are able to offer you the installation and programming of the machine's PLC, complete tool change system, pallet change system, rotary tables with one or more axes, rotary machine heads, etc.

We provide a guarantee for all work done, and within and outside the guarantee period we offer service and maintenance services for your machine tools.

In addition to repair, retrofitting and rebuilding services, we also provide all types of service services and upgrades of electronic and mechanical equipment on machine tools, as well as partial machine overhaul. According to your needs and requirements, we are able to carry out complex modifications of machines so that they fully meet your needs. We are able to offer you the installation and programming of the machine's PLC, complete tool change system, pallet change system, rotary tables with one or more axes, rotary machine heads, etc.

We provide a guarantee for all work done, and within and outside the guarantee period we offer service and maintenance services for your machine tools.