Advanced Technology and Precision

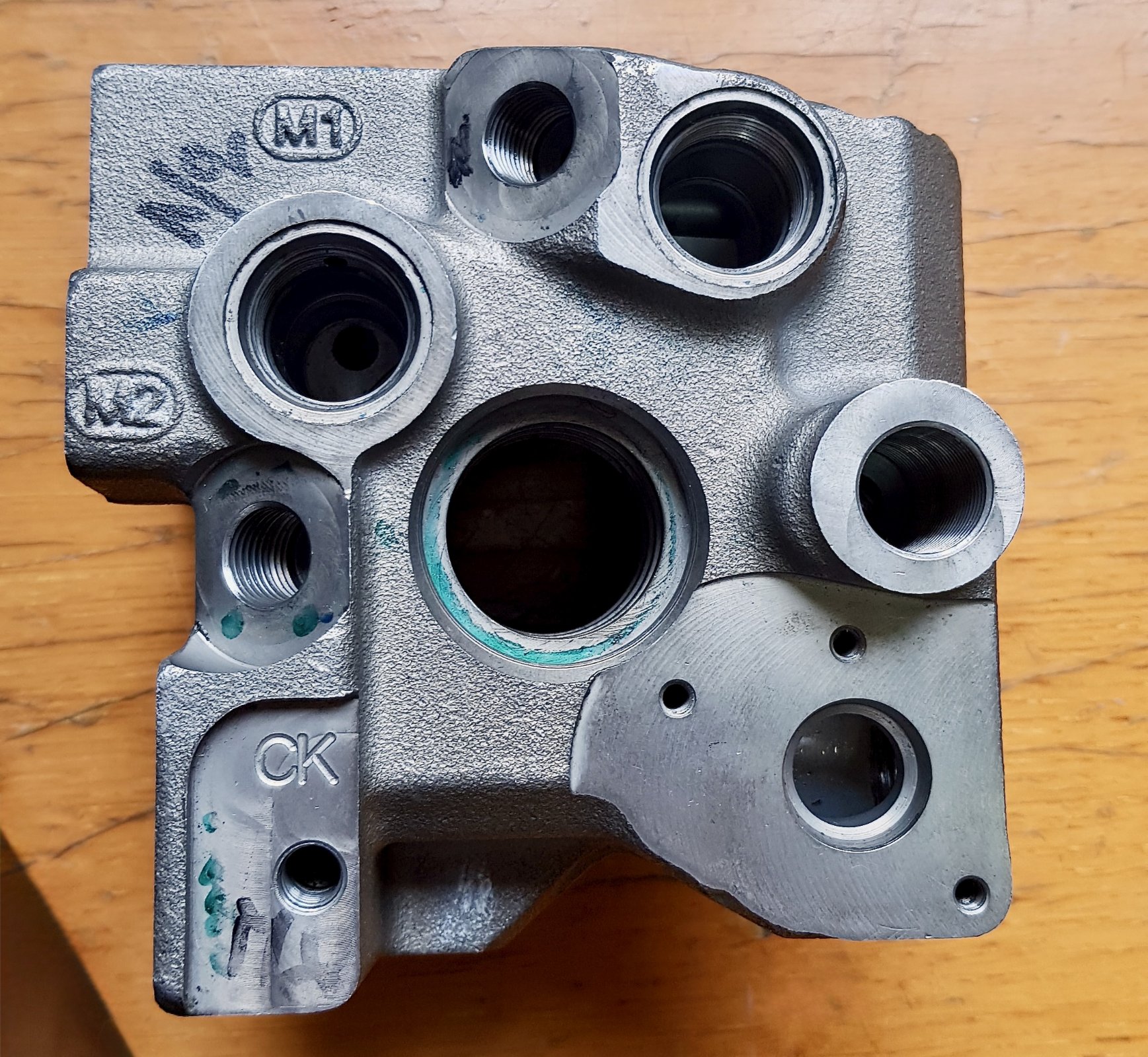

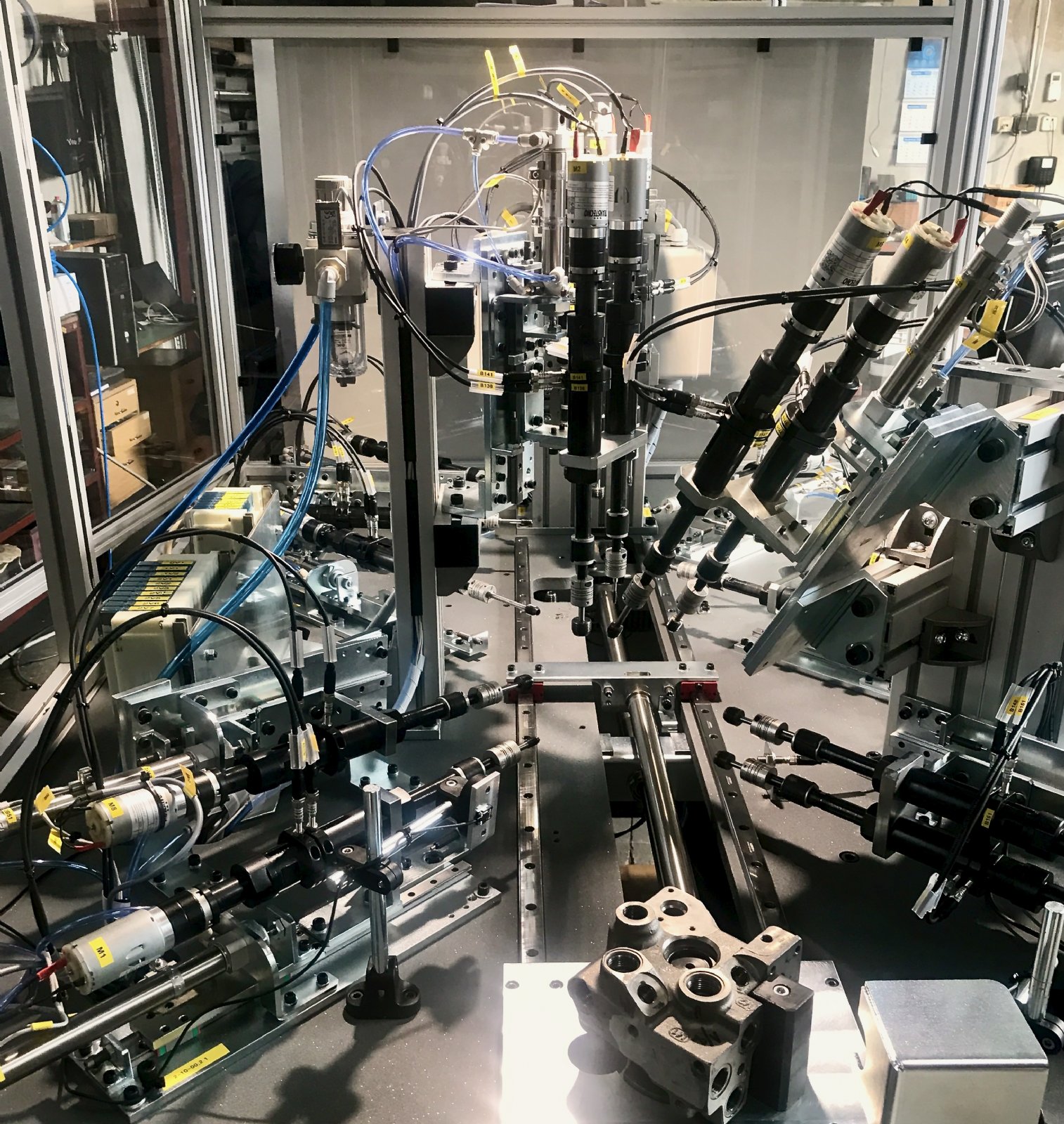

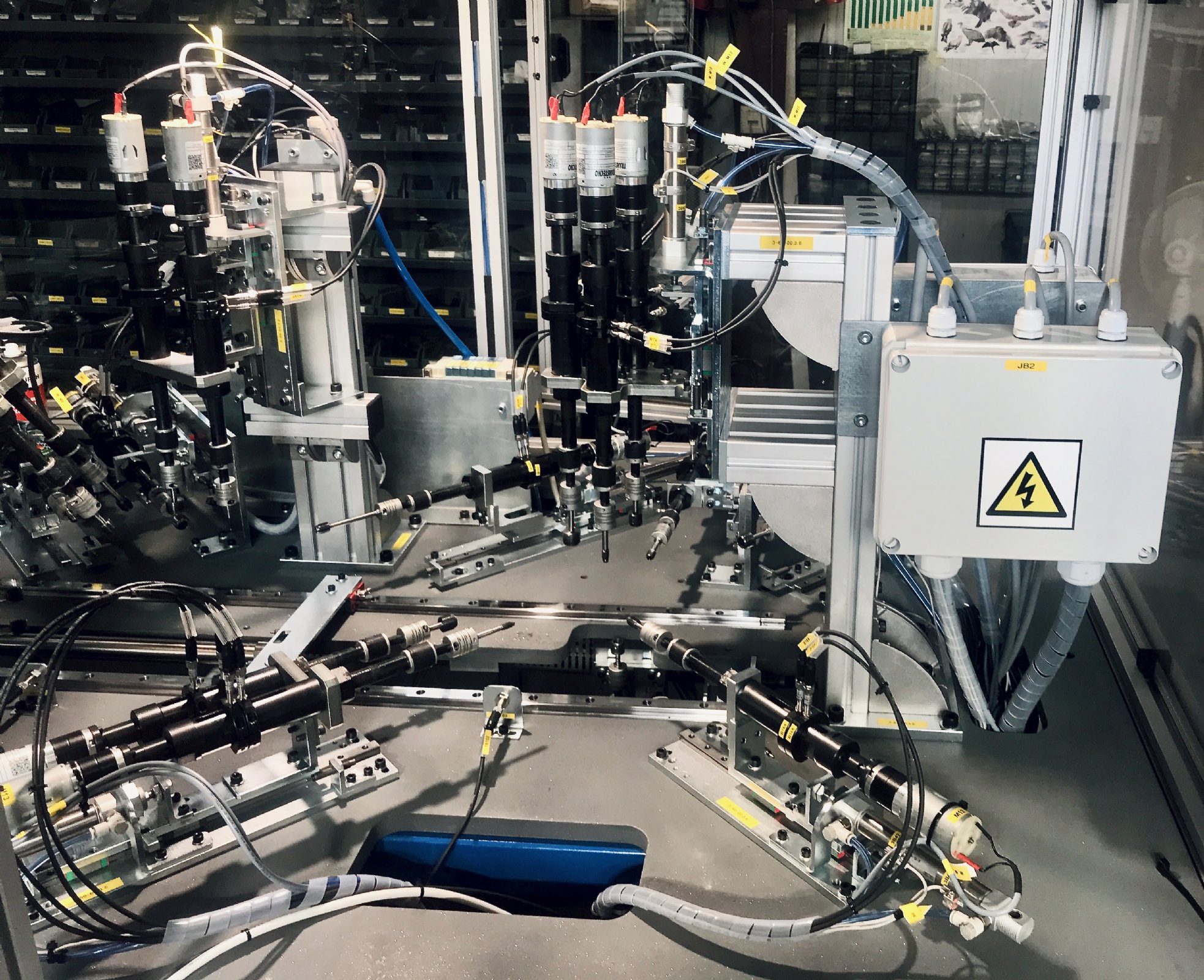

Automatic Thread Control Device for Valve Housing combines innovation, reliability and a high technological standard. It is designed to enable fast, precise and fully reliable thread testing, making it an indispensable tool in modern production.

Fully designed and manufactured by SINEL, this robust device stands out for its top quality and operational safety. Thanks to specially developed thread checkers, DC-driven motors and sensors, maximum precision and repeatability of the process are achieved – every inspection is equally reliable and consistent.

Fully Automated Control Process

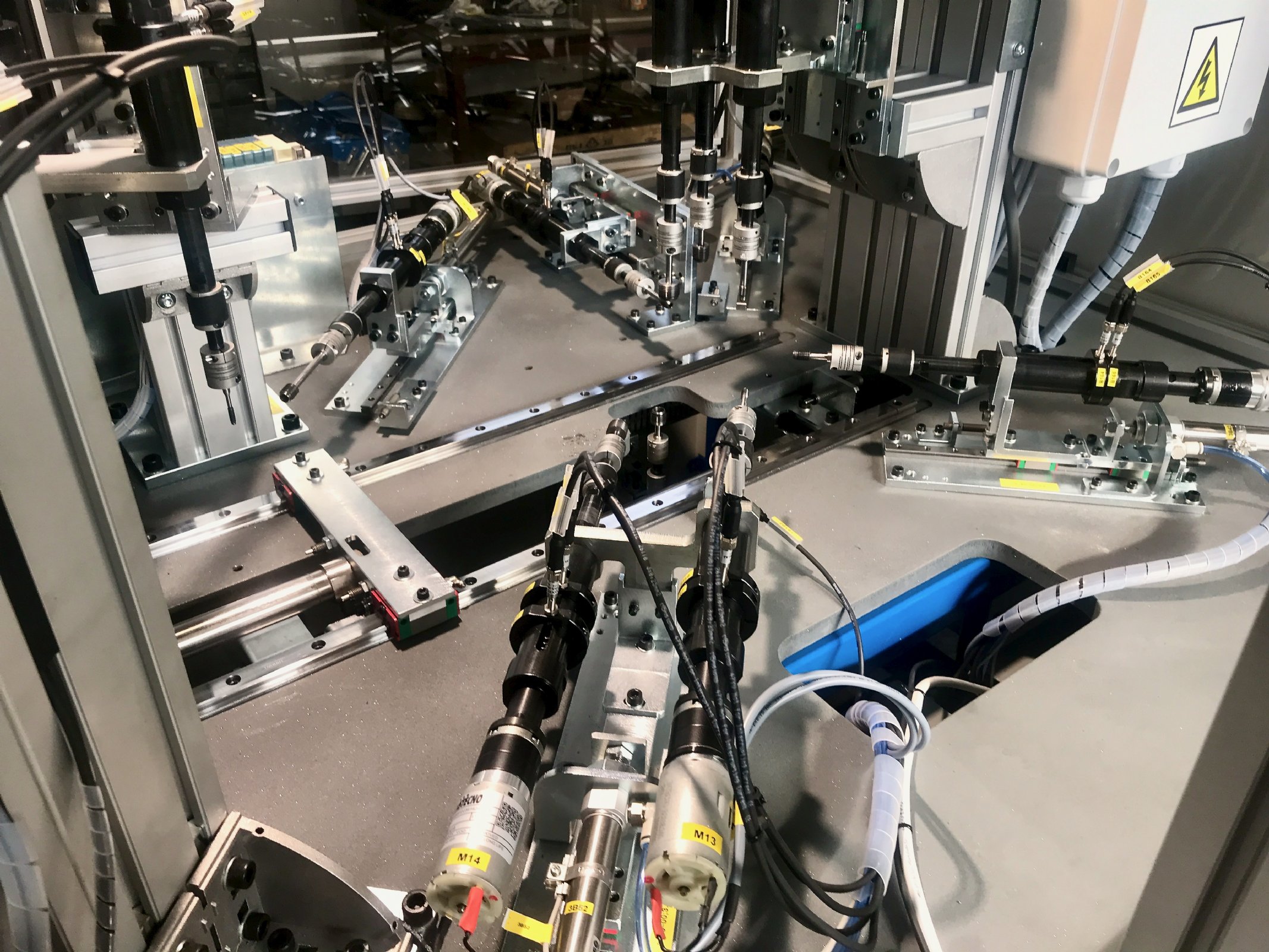

One of the greatest advantages of the device is its fully automated work cycle which minimizes operator intervention. The operator only needs to place the part in the nest and activate the two-hand start function – the device takes care of the rest automatically. ·

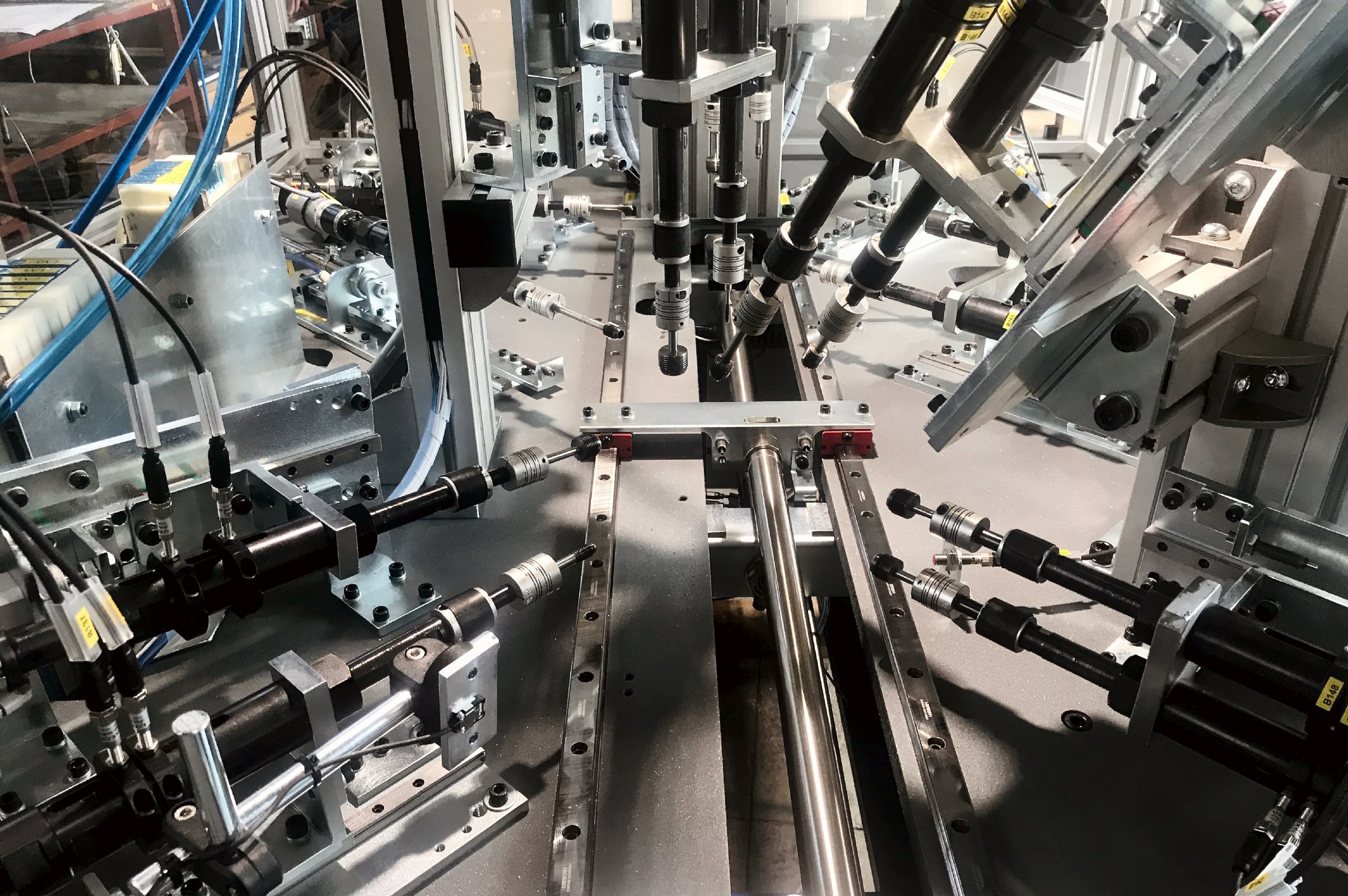

- Part Positioning: Pneumatic actuators with exceptional accuracy move the workpiece to the first measuring station.

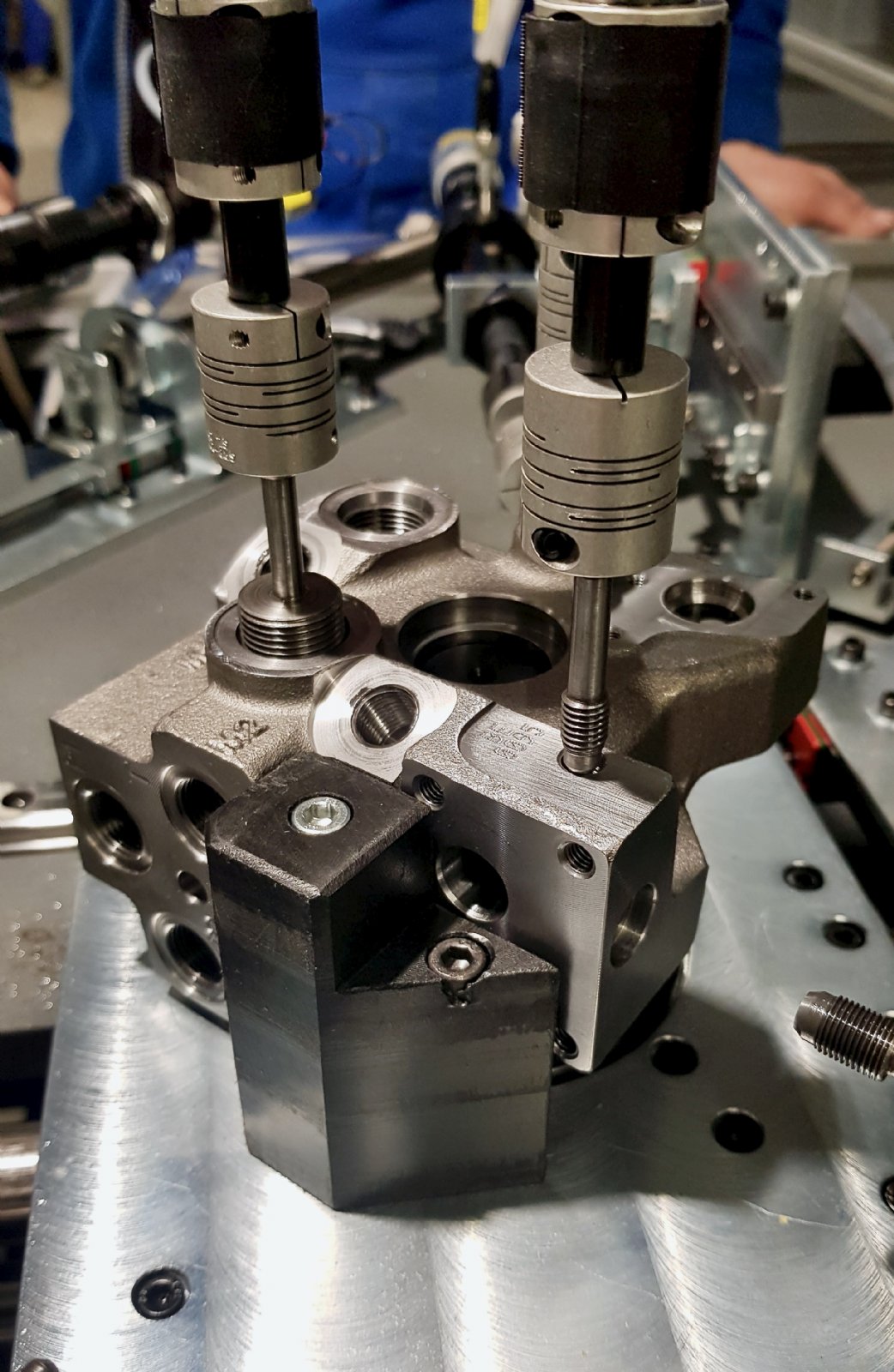

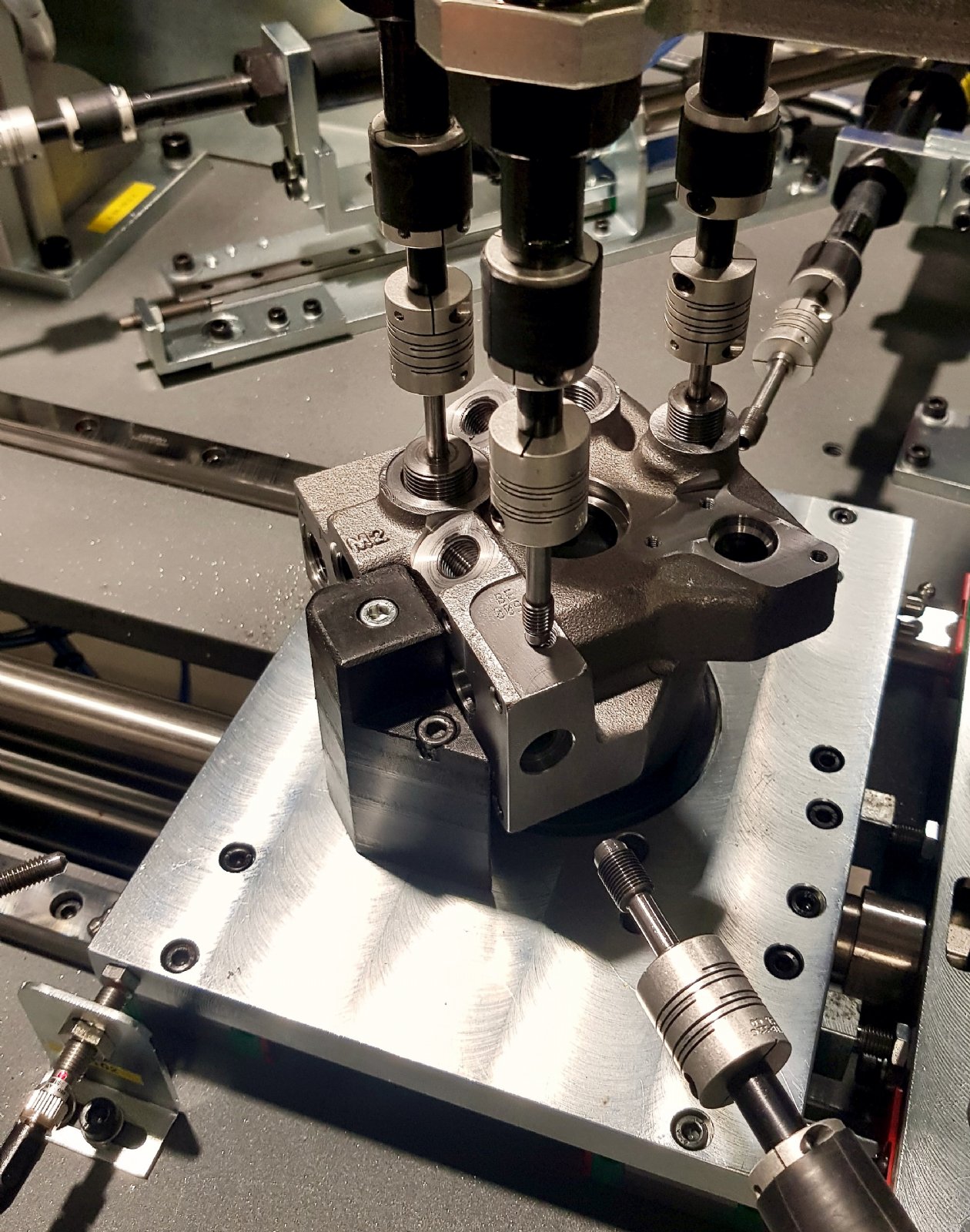

- First Thread Check: Specialized thread checkers precisely verify the correctness of the first set of threads. Driven by pneumatic actuators and DC motors, the checkers screw into the thread, perform a detailed inspection, then automatically unscrew and return to the starting position.

- Automatic Transfer: After a successful first inspection, the nest moves to the next position where the second set of threads is checked.

- Cycle Completion: Upon completion of the second inspection, the nest returns to the initial position, and the inspection result is displayed in real time on the control panel.

This flawlessly coordinated cycle ensures speed, repeatability and safety in every operation.

Safety and Defective Part Detection

If a defective thread is detected, the process stops immediately. The part is returned to the starting position, the defect is clearly indicated on the control panel, and the doors automatically open so the operator can remove the piece.

In the case of a successful inspection, the panel confirms correctness, the doors open, and the operator takes the inspected part ready for the next processing stage. The entire process runs safely, quickly and without risk of error.

Technical Specifications ·

- Dimensions: 2180 × 1300 × 2000 mm

- Weight: 700 kg

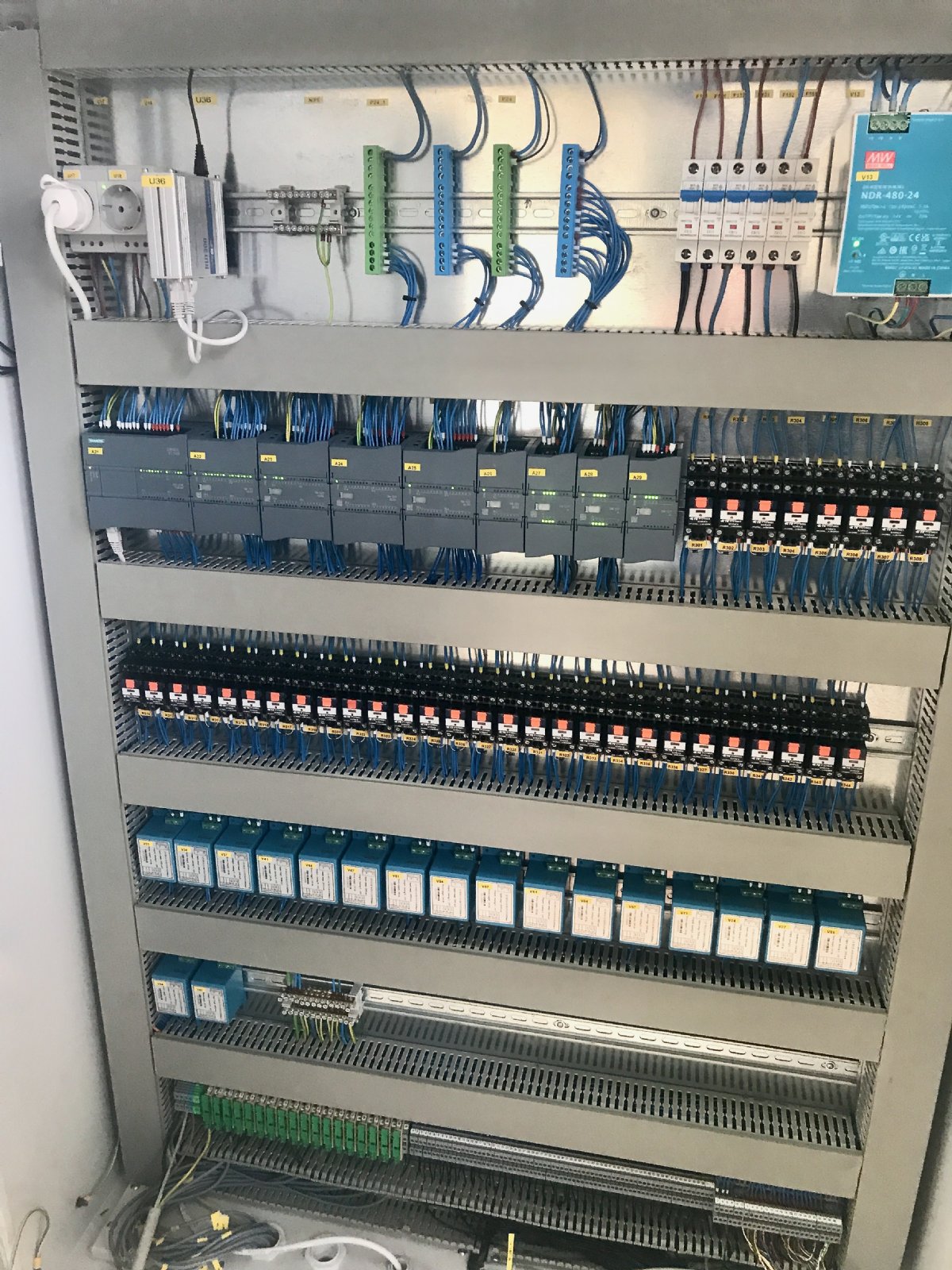

- Power supply: 3 × 400 VAC, 50 Hz

- Installed power: 1.5 kW

- Control power supply: 24 VDC

- Pneumatic connection: min. 6 bar

- Safety: automatic doors, two-hand start, integrated sensors

Advantages ·

- Fast and precise thread inspection

- Fully automated work cycle

- High operator safety

- Guaranteed product quality

- Minimal chance of human error

With robust construction, advanced technology and complete automation, the SINEL Device for thread control sets new standards in production. Its application not only brings increased efficiency and reduced costs but also guarantees consistent quality of every manufactured piece – a key step toward excellence in the industry.

Would you like to learn how this project can improve your business?

Let's discuss your specific needs and explore how our solutions can contribute to your success. Let us show you what makes us different and why partnering with us is better than working with a mere supplier.

Talk to an Expert